Autoline II and Autoline PRO Abrasive Cutting Heads

Product Details:

- Material Stainless Steel

- Coating Polished

- Usage Industrial

- Operate Method Semi Automatic

- Click to View more

Autoline II and Autoline PRO Abrasive Cutting Heads Price And Quantity

- 50 Unit

Autoline II and Autoline PRO Abrasive Cutting Heads Product Specifications

- Stainless Steel

- Polished

- Semi Automatic

- Industrial

Autoline II and Autoline PRO Abrasive Cutting Heads Trade Information

- 1000 Unit Per Month

- 10 Days

- All India

Product Description

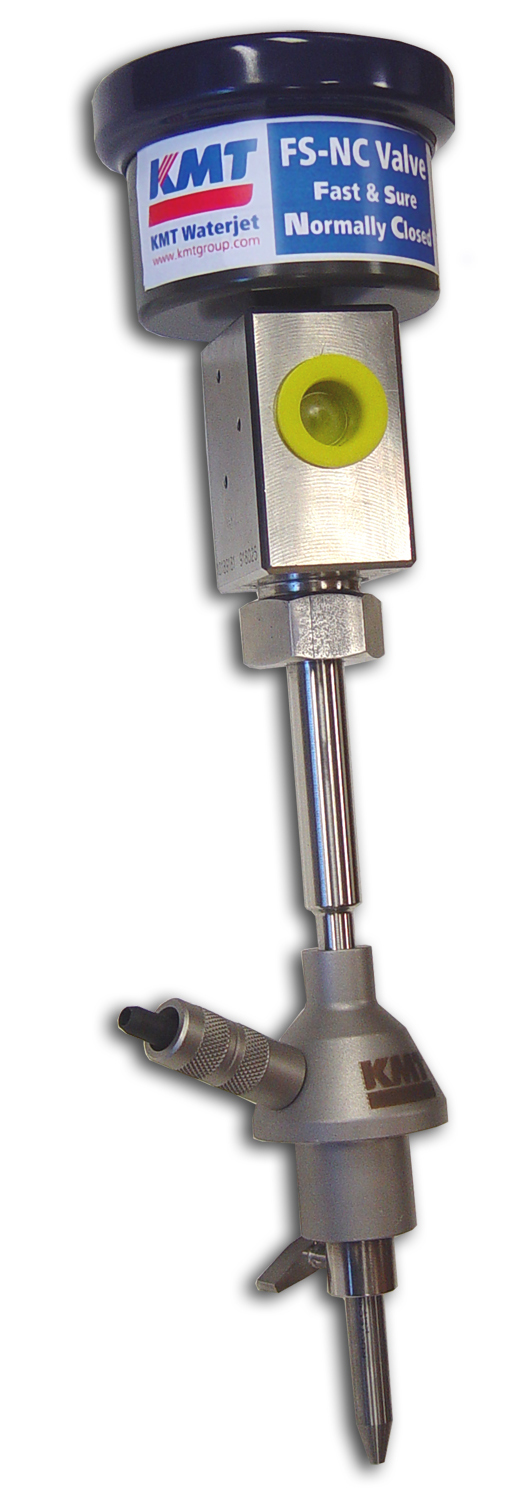

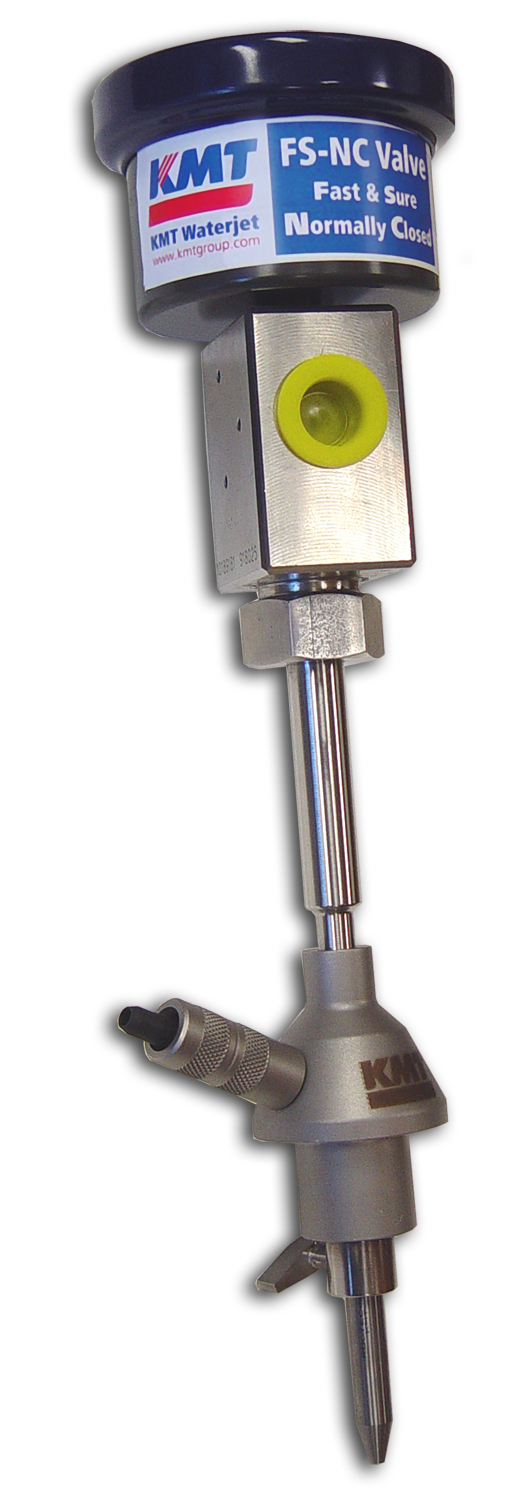

With the cutting heads ACTIVE AUTOLINE II (4000 bar) and ACTIVE AUTOLINE PRO (6200 bar), KMT WATERJET SYSTEMS has developed abrasive cutting head assemblies that provide the best efficiency by utilizing long life components. Thus, maintenance efforts can be reduced and running times extended. The KMT cutting heads feature the following characteristics:

Instant indication of preventable faults

The cutting head is equipped with a leakage bore near the water nozzle. It indicates whether the nozzle is installed correctly and the cutting head is properly secured. Damage to the sealing surfaces of diamond or sapphire nozzles or to the nozzle pipe can thus be easily detected and eliminated.

Pre-filter protects the water nozzle

The pre-filter is installed between the HD line and the nozzle valve body in the adapter. This component reduces the mechanical impact on the water nozzle, as particles are removed from the cutting jet so that they do not cause abrasion to the nozzle. This significantly prolongs the service life of the nozzle and lowers the operating costs.

ACTIVE AUTOLINE II and PRO Easy solution for top level performance

1. The patented tool-free attachment allows for the quick exchange of the water and focusing nozzles

without the need to dismantle the abrasive feed hose.

2. The unique non-metallically welded nozzle base caters for high precision and repetition accuracy.

3. The AUTOLINE II and PRO cutting head includes only three wear parts, namely the orifice, the mixing

chamber and the focusing tube, which are made from extremely wear resistant materials.

4. The nozzle body consists of an exchangeable insert. If worn, simply replace the mixing chamber.

5. Pure-water cuts can be made with the same orifice, so retooling takes only a few seconds.

Notes:

The Product price mentionedis a notional value only and is not the actual price. kindly note all ourproducts are imported and the prices shall be in EUROS. Pleasecontact us on +91 99208 97010 or +9191520 04544 for actual price and formalquotation of the products in line with your requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Maharashtra, India

Maharashtra, India