CLEANLINE I

Product Details:

- Product Type Cold Lamination Machine

- Material Mild Steel

- Capacity 1000 Sheets/Hour

- Voltage 415V

- Power Supply 3 Phase

- Motor Power 2 HP

- Cutting Accuracy 0.2 mm

- Click to View more

CLEANLINE I Price And Quantity

- 10 Piece

- BOPP, PET, PVC and Thermal Films

- Digital Control Panel

- Cold (No Heating)

- Emergency Stop Button & Safety Covers

- Floor Mounted

- Lamination of printing materials, paper, and board

- Imported Silicon Rollers

- Up to 30 m/min

- 1100 mm

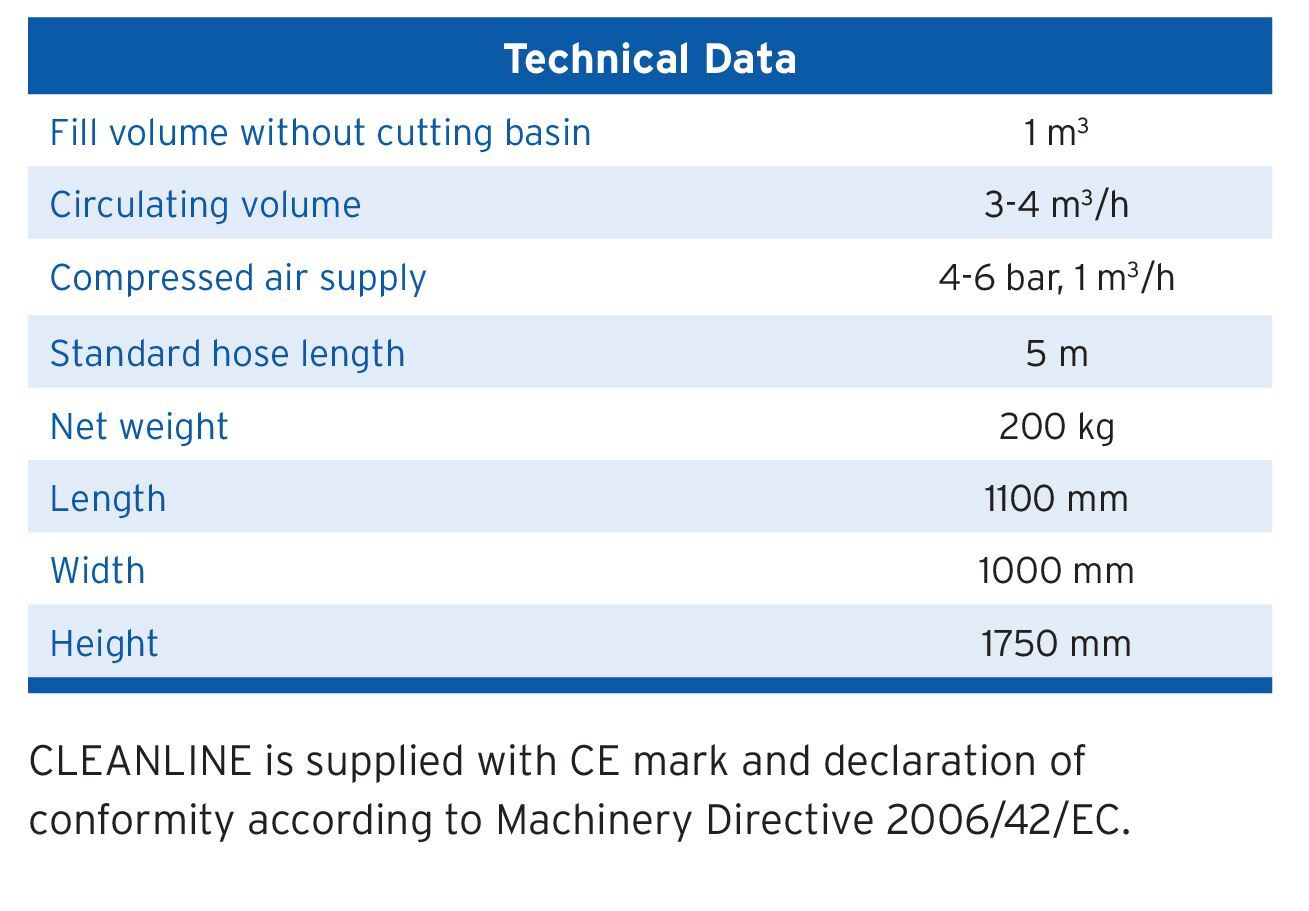

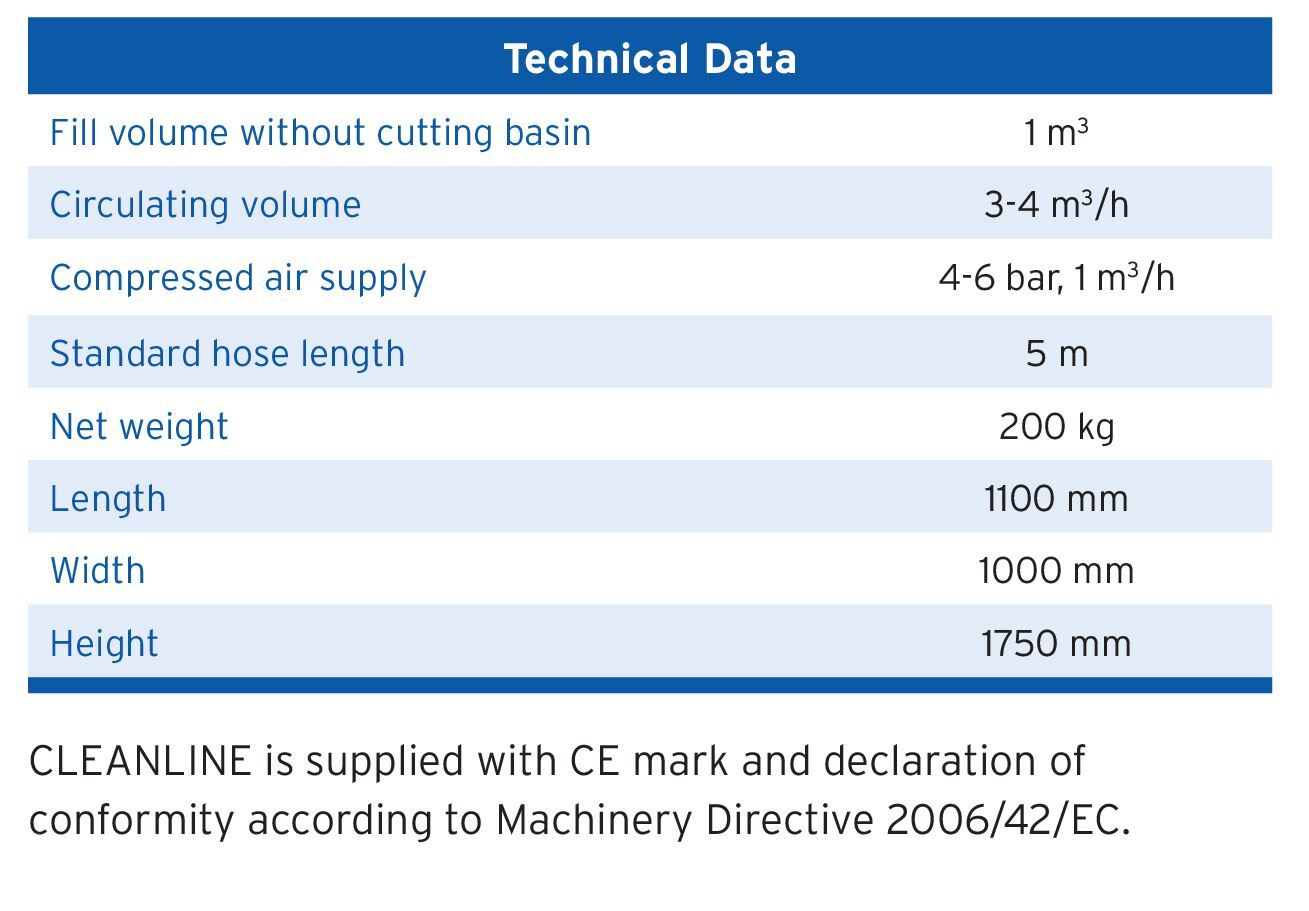

CLEANLINE I Product Specifications

- 700 kg

- Adjustable Pneumatic Pressure

- 2 HP

- Mild Steel

- 0.2 mm

- Flat Table

- Cold Lamination Machine

- 3 Phase

- 415V

- 1000 Sheets/Hour

- 1700 x 1100 x 1200 mm

- BOPP, PET, PVC and Thermal Films

- Digital Control Panel

- Cold (No Heating)

- Emergency Stop Button & Safety Covers

- Floor Mounted

- Lamination of printing materials, paper, and board

- Imported Silicon Rollers

- Up to 30 m/min

- 1100 mm

CLEANLINE I Trade Information

- Mumbai

- All India

Product Description

Efficient desludging

Per minute, the CLEANLINE system removes approx. 50-60 kg of used abrasive from the basin. At this rate, a 3 m x 2 m cutting basin can be desludged in about 90-100 minutes.

Extracting and flushing in one go

The desludging system is equipped with a tube lance which swirls up and sucks in the sludge while at the same time jetting the filtered water back into the cutting basin. The tube lance is manually placed in

the required position where it remains during the cutting process until the dispersion of the abrasive in the basin makes a change of position necessary or the basin is completely deslugded.

Specialized pump for a long lifespan

The CLEANLINE system is actuated by reliable pneumatically driven diaphragm pumps which have been developed specifically for handling aggressive, abrasive and viscous liquids. The pumps are protected against running dry, feature a maintenance-free air control valve, have no shaft seals, are self priming and are protected against overload.

Minimal maintenance

The CLEANLINE is manufactured from high quality components and materials thus guaranteeing long product life and low wear. The pump diaphragms, valve balls and valve seats are tried-and-tested industrial standard products which are easily exchangeable. Feel free to ask your KMT contact to purchase the necessary spare parts.

Notes:

The Product price mentionedis a notional value only and is not the actual price. kindly note all ourproducts are imported and the prices shall be in EUROS. Pleasecontact us on +91 99208 97010 or +9191520 04544 for actual price and formalquotation of the products in line with your requirements.

Advanced Digital Controls for Streamlined Operations

CLEANLINE I is equipped with an intuitive, digital control panel, allowing operators to efficiently manage every aspect of the lamination process. This system gives precise adjustments and real-time monitoring, enhancing your workflow and minimizing downtime. Tailored for both seasoned professionals and new users, the controls are designed for straightforward operation and consistent output quality.

Durable and Precise Lamination Technology

Utilizing imported silicon rollers and a flat cutting table, CLEANLINE I offers superior film application and consistent cutting accuracy of 0.2 mm. With adjustable pneumatic pressure, it accommodates diverse materials, including printing paper, boards, and specialty films. The machine's sturdy mild steel construction ensures reliability for high-volume, demanding environments.

Enhanced Safety and Ergonomic Floor-Mounted Design

Safety is at the forefront with the CLEANLINE I. The emergency stop button and comprehensive safety covers protect operators during use. Its floor-mounted installation and compact footprint (1700 x 1100 x 1200 mm) ensure stability and seamless integration into existing production lines, all while maintaining easy accessibility for routine operation and maintenance.

FAQ's of CLEANLINE I:

Q: How do I operate the CLEANLINE I lamination machine?

A: CLEANLINE I is operated via a user-friendly digital control panel that allows adjustment of speed, pressure, and film type. Simply load your material onto the flat table, select your lamination film among BOPP, PET, PVC, or thermal varieties, and follow the instructed sequence for precise, efficient lamination.Q: What materials and films can be used with CLEANLINE I?

A: This machine is compatible with BOPP, PET, PVC, and thermal films, making it suitable for laminating a variety of printing materials, paper, and board. The adjustable pneumatic pressure system ensures optimal bonding for each material type.Q: When is the CLEANLINE I recommended for use in my production process?

A: CLEANLINE I is ideal for businesses requiring high-volume, high-accuracy lamination-such as print shops, packaging facilities, or manufacturers handling sheets, boards, and printed materials-thanks to its fast operating speed, capacity, and superior cutting accuracy.Q: Where should the CLEANLINE I be installed?

A: This floor-mounted lamination machine should be positioned on a stable, level surface within your production area. Ensure proximity to a 3-phase, 415V power supply and sufficient clearance for safe operation and maintenance.Q: What is the lamination process like with CLEANLINE I?

A: The process involves feeding sheets onto the flat cutting table, applying the selected film through imported silicon rollers, and enabling cold lamination (no heating required). The machine maintains a steady operating speed up to 30 m/min and achieves precise sheet cutting, all managed from the control panel.Q: How does the CLEANLINE I ensure operator safety?

A: Operator safety is prioritized with the inclusion of emergency stop buttons and protective safety covers. These features help prevent accidental contact with moving parts and empower you to halt operations immediately if needed.Q: What benefits does CLEANLINE I offer compared to other laminators?

A: CLEANLINE I stands out for its high sheet capacity (up to 1000 sheets/hour), impressive cutting accuracy (0.2 mm), maintenance-friendly design, and safety enhancements. Its robust build and adaptable pressure system allow efficient lamination across a broad range of materials, reducing waste and maximizing productivity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Maharashtra, India

Maharashtra, India