H20 JET 50 High Pressure Pump - 4136 bar

Product Details:

- Product Type High Pressure Pump

- Material Stainless Steel

- Capacity 50 HP

- Voltage 415 V

- Power Supply Three Phase / 50 Hz

- Motor Power 37 kW

- Cutting Accuracy 0.1 mm

- Click to View more

H20 JET 50 High Pressure Pump - 4136 bar Price And Quantity

- 1 Piece

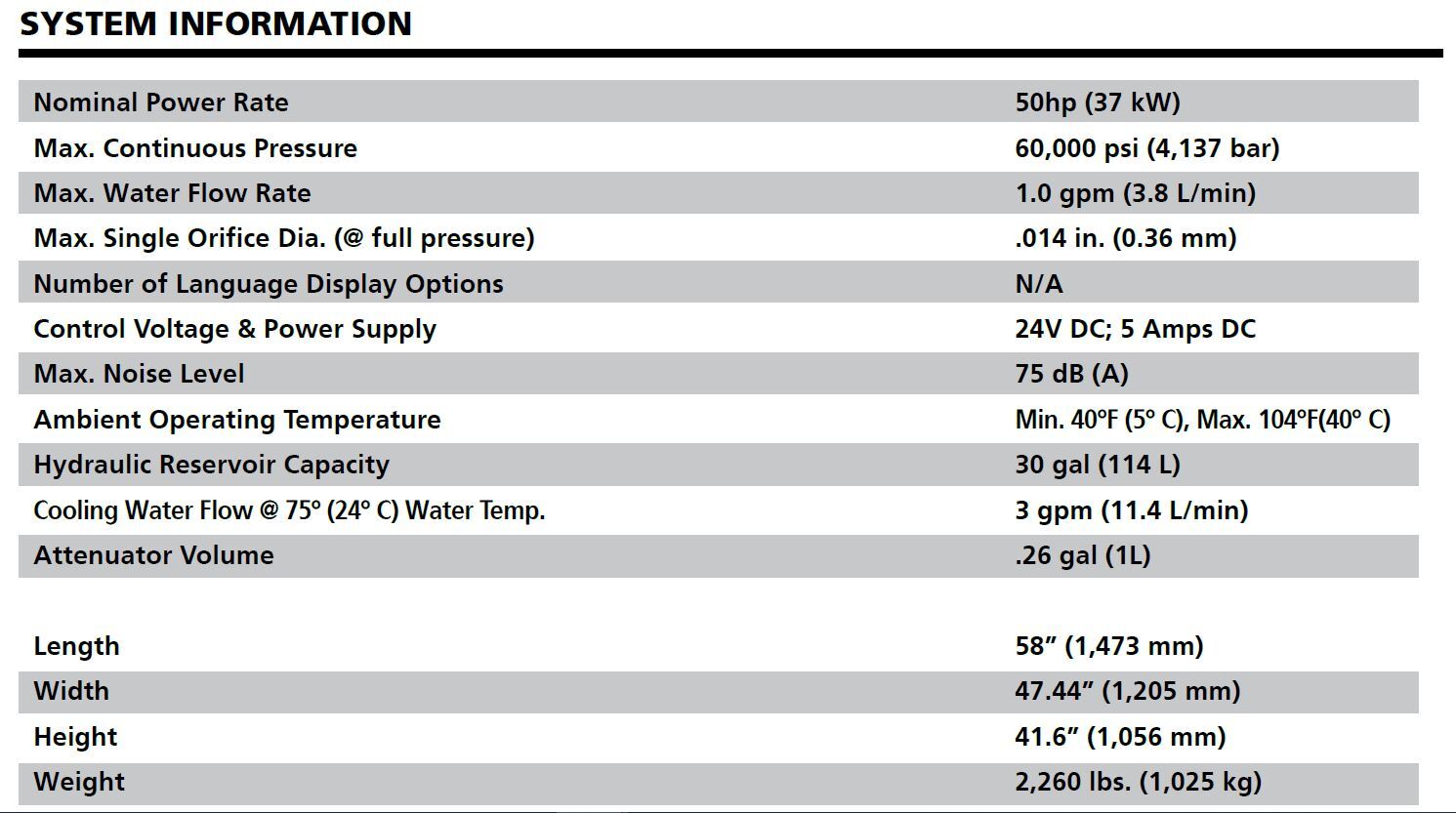

H20 JET 50 High Pressure Pump - 4136 bar Product Specifications

- Stainless Steel

- High Pressure Pump

- 37 kW

- 415 V

- Three Phase / 50 Hz

- 4136 bar

- 0.1 mm

- 1200 kg

- 1800 x 900 x 1200 mm

- 50 HP

H20 JET 50 High Pressure Pump - 4136 bar Trade Information

- 1 Piece Per Month

- 4 Months

- All India

Product Description

The KMT Waterjet H20 JET 50 pump uses superior intensifier

technology for proven performance to provide users with a

durable reliable water jet pump

The H20 JET 50 also features the all new low profile cabinetry

design for easy access to pump controls and components along

with 60000psi operating pressure to cut steel aluminum

stone and much more

The H20 JET 50 also is an all new compact three phase

pump design for quick seal change with operating pressure

at 60000psi

H20 JET 50 Features

PLC Based Controls

Basic Control for Pump On/Off E-Stop

Hydraulic Shift

Manual Cooling Water Valve Oil Water Heat Exchanger

Remote Start/Stop E-Stop Hi/Low Panel

Booster Pump w10 Micron Filter and Pressure Gauge

Return Line Oil Filter with Service Indicator

Dual Pressure Compensator Included

Low Inlet Water Pressure Safety Switch 30psi

60000 psi Design Pressure

H20 JET 50 Features Contd.

Variable Displacement Axial Piston Pump

Continuous Recirculation Pump for Cooling System

Manual Pressure Control

Hi Temp and Low Level Oil Safety Switch

Oil Water Heat Exchanger

Auto Bleed Down Valve

Rugged Powder Coated Finish

Vibration Isolation Pads on Motor

Oil Temperature Level Sight Gauge

Electrical Junction Box

3 Phase Motor

Notes:

The Product price mentioned is a notional value only and is not the actual price. kindly note all our products are imported and the prices shall be in EUROS. Please contact us on +91 99208 97010 or +91 91520 04544 for actual price and formal quotation of the products in line with your requirements.

Advanced Water Jet Cutting Performance

The H2O JET 50 delivers exceptional water jet cutting and surface preparation performance with its powerful 4136 bar pressure and precision nozzles. Its robust stainless steel build and chrome-plated plunger ensure a long-lasting solution for demanding industrial environments, making it ideal for automation-driven operations.

Built for Safety and Reliability

Equipped with a comprehensive set of safety features, including a pressure relief valve and emergency stop, the H2O JET 50 offers peace of mind during high-pressure cutting tasks. The integrated heat exchanger and centralized lubrication system improve operational reliability and maximize equipment lifespan.

Versatile and Efficient Operation

This pump operates on a three-phase, 415V/50Hz power supply and supports nozzle diameters from 0.25 mm to 0.45 mm. Its automatic grade compatibility and accurate cutting capabilities (0.1 mm) make it suitable for a wide range of applications, from fabrication to precise surface finishing.

FAQs of H20 JET 50 High Pressure Pump - 4136 bar:

Q: How is the H2O JET 50 High Pressure Pump used in water jet cutting applications?

A: The H2O JET 50 is specifically designed for water jet cutting by generating ultra-high-pressure water streams (up to 4136 bar) necessary to cut materials with high precision. Its consistent flow rate and adjustable nozzle diameters allow for accurate and efficient cutting across various surfaces.Q: What safety mechanisms are integrated into the H2O JET 50?

A: This pump includes a pressure relief valve and an emergency stop feature to protect both the operator and the equipment during operation, minimizing risks associated with high-pressure water jet processes.Q: Where is the H2O JET 50 typically installed and used?

A: Ideal for industrial environments, the H2O JET 50 is commonly installed in manufacturing units across India for applications such as water jet cutting, metal fabrication, and precise surface preparation.Q: What are the benefits of the centralized automatic lubrication system in this pump?

A: The centralized automatic lubrication system ensures all moving parts are consistently lubricated, reducing maintenance frequency, preventing wear, and extending the lifespan of the pump.Q: When should the high pressure seal kit be checked or replaced?

A: It is recommended to inspect the high pressure seal kit at regular maintenance intervals or whenever there is a noticeable drop in pressure or leakage, to ensure optimal performance and safety.Q: How does the integrated heat exchanger contribute to pump performance?

A: The integrated heat exchanger helps maintain stable operating temperatures, allowing the pump to operate efficiently even during prolonged or intensive cutting tasks, thus preventing overheating.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Maharashtra, India

Maharashtra, India