STREAMLINE VI-50 High Pressure Pump - 4136 bar

Product Details:

- Product Type High Pressure Pump

- Material Stainless Steel

- Capacity 2.5 L/min

- Voltage 415 V

- Power Supply Three Phase, 50 Hz

- Motor Power 37 kW

- Cutting Accuracy 0.1 mm

- Click to View more

STREAMLINE VI-50 High Pressure Pump - 4136 bar Price And Quantity

- 1 Unit

STREAMLINE VI-50 High Pressure Pump - 4136 bar Product Specifications

- High Pressure Pump

- 415 V

- 37 kW

- 1500 kg

- Stainless Steel

- 2.5 L/min

- 4136 bar (60000 psi)

- 0.1 mm

- Three Phase, 50 Hz

- 1500 x 900 x 1400 mm

STREAMLINE VI-50 High Pressure Pump - 4136 bar Trade Information

- All India

Product Description

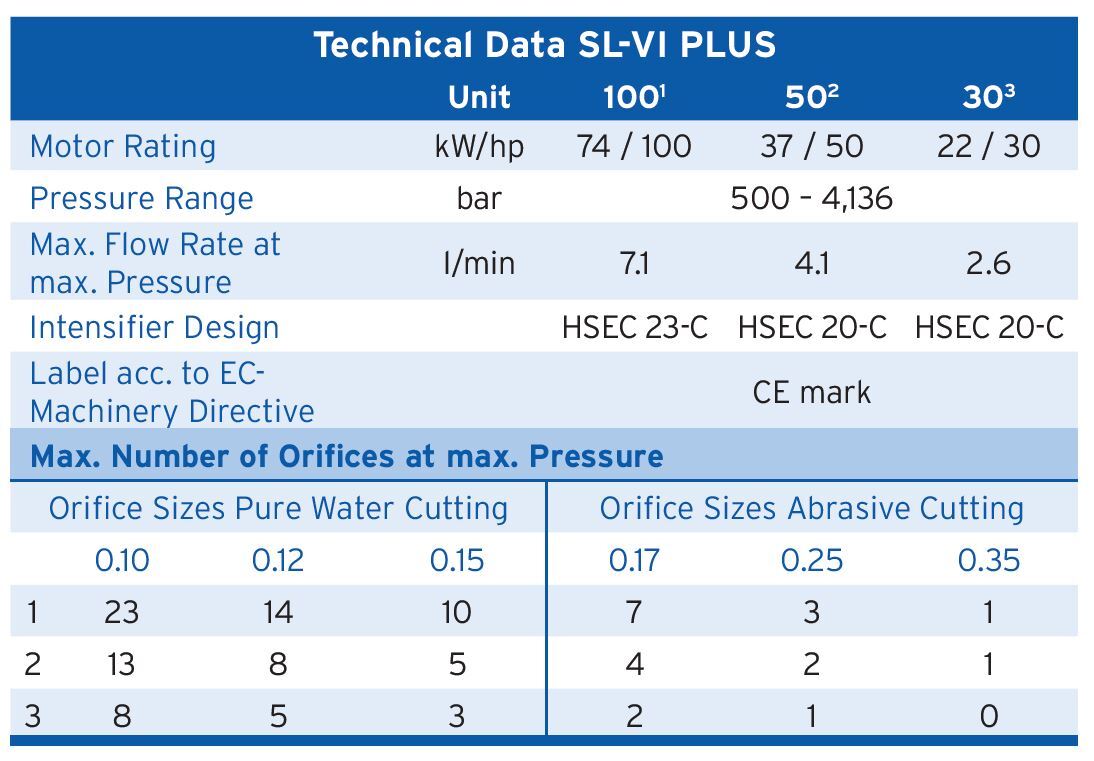

With the new series of STREAMLINE SL-VI high pressure pumps for waterjet cutting, KMT Waterjet Systems optimizes their complete range of high pressure intensifier pumps. Based on four frames indifferent sizes, the SL-VI series will grant the KMT customers an unprecedented choice of configuration possibilities. And while being based on tried and tested technology, the SL-VI comes up with some considerable improvements compared to the predecessor model. Working pressure of up to 4,136 bar The pump units are available in three different power rates (22, 37 and 74 kW). Wherever required, the STREAMLINE SL-VI supplies high pressure water of up to 4.136 bar. In those areas where such a high pressure is not needed, the STREAMLINE SL-VI can cut material at a lower pressure. Improved motor performance The motor of the STREAMLINE SL-VI pumps allows for multi input voltages and has been upgraded toIE3 according to the norm EC 640/2009. This leads to an optimized motor efficiency: Compared to previous models, the pump can create a higher flowrate of the high pressure water at the same motor rating, thus increasing the maximum possible orifice size and with it the cutting system's productivity. Patented intensifier technology The new patented Curve-On-Curve Design of our intensifiers allows for a longer lifetime of the cylinder body / seal head connection. The optimized geometry of the metal-on-metal seals facilitates the installation and endures more maintenance cycles than conventional technologies.

Notes:

The Product price mentioned is a notional value only and is not the actual price. kindly note all our products are imported and the prices shall be in EUROS. Please contact us on +91 99208 97010 or +9191520 04544 for actual price and formal quotation of the products in line with your requirements.

Precision and Efficiency for Industrial Cutting

Experience exceptional cutting precision with the STREAMLINE VI-50, offering a cutting accuracy of 0.1 mm. Its high pressure capacity (4136 bar) and maximum orifice size of 0.33 mm make it ideal for demanding applications in waterjet and industrial cutting, ensuring clean, efficient results on a variety of materials.

Advanced Safety and User Control

Safety is paramount in the STREAMLINE VI-50, equipped with automatic overload protection and an emergency stop switch. Easy operation is ensured through a PLC controlled system, while its three-phase, 415V power supply supports continuous and reliable industrial use.

Durable Design for Continuous Operation

Constructed from stainless steel, this pump endures rigorous industrial environments. Its oil tank capacity of 120 L and water-cooled system allow for sustained high-performance across operating temperatures of 5C to 45C. The streamlined, compact design (1500 x 900 x 1400 mm) fits seamlessly into various workspace layouts.

FAQ's of STREAMLINE VI-50 High Pressure Pump - 4136 bar:

Q: How does the STREAMLINE VI-50 High Pressure Pump enhance industrial cutting applications?

A: The STREAMLINE VI-50 ensures superior cutting accuracy and high-pressure operation, making it ideal for industrial and waterjet cutting. With a pressure of 4136 bar and PLC control, users achieve clean, precise cuts with minimal material waste, boosting production efficiency.Q: What safety features are included with the STREAMLINE VI-50?

A: This pump offers automatic overload protection and an emergency stop switch, ensuring operational safety. These features help safeguard both the operator and the equipment during intensive cutting tasks.Q: When should the STREAMLINE VI-50 be used over lower-pressure systems?

A: Choose the VI-50 for applications requiring intricate, high-precision cutting, or when working with thick or tough materials. Its high pressure and precise orifice size make it especially suitable for complex industrial projects.Q: Where is the STREAMLINE VI-50 typically installed?

A: The pump is commonly deployed in manufacturing plants, fabrication shops, and industrial facilities across India, where consistent, high-power waterjet cutting is essential for daily operations.Q: What is the benefit of the water-cooled system in this pump?

A: The water-cooled system maintains optimal operating temperatures, reduces wear on internal components, and allows for prolonged, uninterrupted use, thereby increasing the pump's lifespan and performance.Q: How is the STREAMLINE VI-50 operated and monitored?

A: The system features PLC control for precise operation and easy monitoring, enabling users to adjust parameters, manage processes, and receive real-time feedback for improved productivity.Q: What materials can be processed using this high-pressure pump?

A: The STREAMLINE VI-50 is suitable for cutting a wide range of materials, including metals, glass, ceramics, and composites, thanks to its high pressure and fine orifice size.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Maharashtra, India

Maharashtra, India